IP-Schutzklassen sind wichtig, da sie bestimmen, wie gut ein Steckverbinder Staub und Wasser widersteht. Die richtige Schutzklasse verlangsamt Korrosion, hält den Kontaktwiderstand stabil und reduziert ungeplante Ausfallzeiten. Für EV-Steckverbinder, es gibt ein paar Nuancen, die sich direkt auf den Einsatz im Feld auswirken: Wasserstrahltests und Tauchtests sind unterschiedlich, die Bewertungen können sich ändern, wenn der Stecker eingesteckt oder nicht eingesteckt ist, und auf der Fahrzeugseite werden häufig Bewertungen mit dem Suffix K verwendet, die für starkes Spritzwasser und Wasserabspritzen auf der Straße ausgelegt sind.

Was Ihnen eine IP-Bewertung tatsächlich sagt

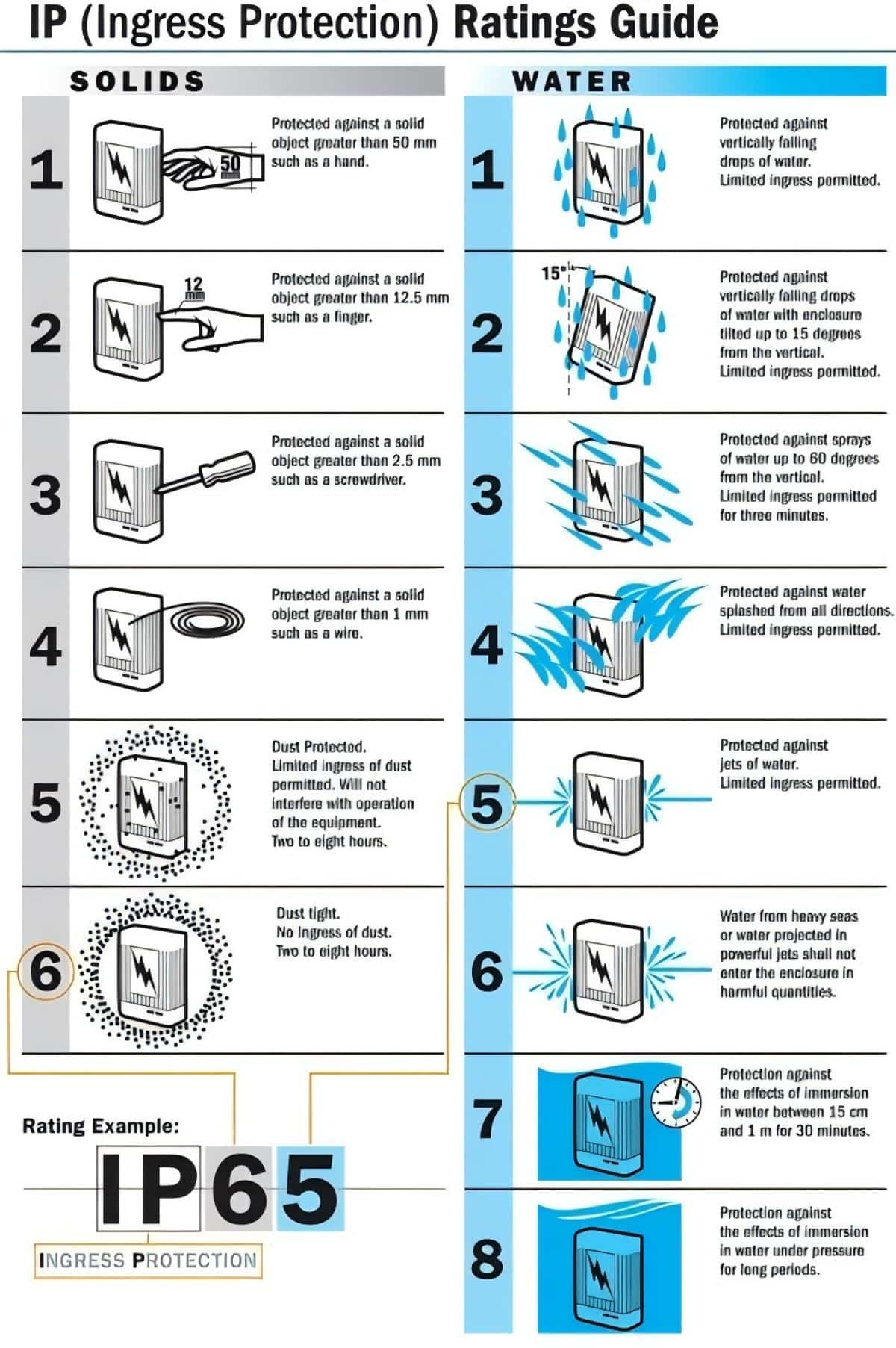

Ein IP-Code besteht aus zwei Zahlen: Die erste deckt das Eindringen von Feststoffen ab, die zweite das Eindringen von Wasser. Die Wassertests sind nicht kumulativ. Das Bestehen eines Tauchtests bedeutet nicht, dass ein Produkt auch starke Wasserstrahltests besteht, und umgekehrt gilt das Gleiche. Deshalb geben einige Datenblätter zwei Wasserklassen an, z. B. IPX6 und IPX7, um die Leistung sowohl unter Strahl- als auch unter Tauchbedingungen zu belegen.

Warum sich der Schutz vor eindringenden Medien auf die Lebensdauer von Steckverbindern auswirkt

Feuchtigkeit und Feinpartikel schädigen Metallkontakte schnell und können Polymer- oder Elastomerdichtungen beeinträchtigen.. Sobald Verunreinigungen in den Stifthohlraum oder den Kabelausgang gelangen:

• Wenn der Kontaktwiderstand zunimmt, entsteht unter elektrischer Belastung Wärme.

• Die Beschichtung nutzt sich schneller ab und es kann zu geringfügiger Lichtbogenbildung kommen.

• Dichtungen altern vorzeitig, insbesondere nach Frost-Tau-Wechseln oder wiederholtem Hochdruckreinigen.

Ein Steckverbinder mit geeigneter IP-Schutzart begrenzt das Eindringen von Staub und Wasser in das Gehäuse, den Kontaktbereich und den Zugentlastungsbereich. In der Praxis bedeutet dies weniger zeitweilige Fehler, weniger ausgelöste Schutzvorrichtungen und längere Wartungsintervalle.

Gekoppelt vs. ungekoppelt und warum „Kabelausgang“ eine eigene Zeile verdient

Viele Baugruppen verfügen je nach Bundesland über unterschiedliche Schutzstufen:

• Gepaart (in den Einlass eingesteckt): Die Schnittstelle ist abgedichtet, daher ist der Wasserschutz normalerweise höher.

• Nicht verbunden (freiliegende Stifte): Der Kontaktbereich ist offen, daher kann die Nennleistung niedriger sein.

• Kabelausgang (an der Zugentlastung/Umspritzung): Dieser Pfad hat oft eine eigene Bewertung, da bei einer schwachen Versiegelung Kapillaren entlang der Leiter eindringen können.

Achten Sie beim Überprüfen einer Spezifikation auf klare, bundesstaatsspezifische Erklärungen und nicht auf eine einzelne Überschriftennummer.

Fahrzeug-Einlässe und das K-Suffix

Auf der Fahrzeugseite finden Sie häufig IP6K7, IP6K5 oder sogar IP6K9K. Das K-Suffix wird für Straßenfahrzeugbedingungen mit definiertem Sprühdruck, Winkel und manchmal Hochtemperaturwasser verwendet. Es zeigt an, dass der Einlass für Straßenspritzer und professionelles Abspritzen innerhalb definierter Grenzen ausgelegt ist. Es berechtigt nicht dazu, einen heißen Hochdruckstrahl aus nächster Nähe direkt auf eine freiliegende Steckerfläche zu richten.

Typische Bewertungen, die Sie finden werden

Standort oder Bundesland | Typische Marktbewertungen | Was der Test betont | Praktische Bedeutung im Feld |

AC-Stecker und Kabel, verbunden | IP54–IP55 | Spritz- und Standarddüsen | Funktioniert zuverlässig bei Regen, wenn das Gerät eingesteckt ist; im Leerlauf Kappen verwenden |

Anschlusskabelausgang | Bis zu IP67 | Vorübergehendes Eintauchen am Austrittsweg | Bessere Abdichtung bei Zugentlastung; verlangsamt das Eindringen von Kapillaren |

DC/HPC-Steckergehäuse | Oft IP67 | Eintauchen | Hilfreich bei Stürmen oder Wasseransammlungen; bedeutet nicht, dass es strahlfest ist |

Fahrzeug-Einlassbaugruppe | IP6K7 / IP6K5 / IP6K9K | Staubdicht und tauch- oder strahlfest | Konzipiert für Straßenspritzer und -reinigungen unter kontrollierten Bedingungen |

Stationsgehäuse | IP54 / IP56 / IP65 | Vom Spritzwasser bis zum starken Strahl | Die Gehäusebewertung ist von der Steckverbinderbewertung getrennt |

Auswählen der richtigen Bewertung für Ihre Site

Innendepots und überdachte Parkplätze

IP54 am Stecker ist normalerweise ausreichend. Behalten Sie die Staubkappen auf dem Stecker, wenn er nicht angeschlossen ist, und planen Sie schnelle Sichtprüfungen ein.

Öffentliche Plätze im Freien

Achten Sie bei freiliegenden Anschlüssen auf IP55 und bei Gehäusen auf IP56 oder höher, um Regen und Spritzwasser standzuhalten. Überprüfen Sie die Dichtungen regelmäßig.

Küstennahe, staubige oder sandige Standorte

Achten Sie auf eine staubdichte erste Ziffer und einen stärkeren Wasserschutz. Führen Sie regelmäßige Wartungsarbeiten durch, um die Kappen, O-Ringe und die äußere Kabelhülle zu reinigen. Achten Sie auf Salzrückstände im Kontaktbereich.

Flottenhöfe mit regelmäßiger Reinigung

Wählen Sie Anschlüsse und Einlässe, die für Hochdruck-Sprühbedingungen geeignet sind. Veröffentlichen Sie Reinigungsregeln: Vermeiden Sie kurze, heiße Strahlen auf die freiliegende Pistolenoberfläche; halten Sie Abstand und Winkel ein; lassen Sie das Gerät vor der Reinigung abkühlen.

Hochwassergefährdete oder sturmexponierte Standorte

IP67 auf Steckergehäusen schützt vor zeitweiligem Untertauchen. Kombinieren Sie dies mit einem Trocknungsprotokoll nach Unwettern: Entleeren, lüften und die Isolierung überprüfen, bevor Sie die Verbindung wieder in Betrieb nehmen.

Checkliste für Beschaffung und Qualitätssicherung

Zustandsstrahl und Immersion getrennt

Wenn Sie beides benötigen, geben Sie beides an (z. B. IPX6 und IPX7). Gehen Sie nicht davon aus, dass das eine das andere impliziert.

Fordern Sie bundeslandspezifische Erklärungen an

Bitten Sie Lieferanten, den Schutz für den gesteckten, ungesteckten und Kabelausgangszustand aufzulisten. Fordern Sie Zeichnungen an, in denen die Dichtungspositionen und Kompressionsrichtungen markiert sind.

Fahrzeugseitige Anforderungen einbeziehen

Definieren Sie K-Suffix-Bewertungen am Einlass, um sie an echte Waschpraktiken und lokale Straßenbedingungen anzupassen.

Wareneingangsprüfung planen

Replizieren Sie die definierte Düse, den Durchfluss, den Druck, den Abstand, die Temperatur und den Winkel. Notieren Sie Parameter und Ergebnisse. Überprüfen Sie nach dem Test Dichtungen und Kontakte und achten Sie auf einen Anstieg des Kontaktwiderstands.

Definieren Sie die Wartungsdokumentation

Fordern Sie eine einfache, visuelle Wartungscheckliste (Verwendung der Kappe, Zustand der Dichtung, freie Abflusswege) und Austauschintervalle für Verbrauchsdichtungen.

Wartungspraktiken zur Verlängerung der Lebensdauer

• Halten Sie Kappen und O-Ringe sauber. Ersetzen Sie verhärtete oder beschädigte Dichtungen.

• Vermeiden Sie es, die freiliegende Fläche des Steckverbinders mit heißen Hochdruckstrahlen aus nächster Nähe zu bestrahlen.

• Nach starkem Regen, Wäschewaschen oder Sturm eine Trocknung bei niedriger Temperatur einplanen oder für gründliches Lüften sorgen.

• Schulen Sie Ihr Personal darin, wie sich der gepaarte bzw. ungepaarte Zustand auf den Schutz auswirkt und warum Obergrenzen wichtig sind.

Was IP nicht abdeckt (aber dennoch die Haltbarkeit beeinflusst)

Eine IP-Einstufung berücksichtigt nicht die IK-Stoßfestigkeit, UV-Beständigkeit, Salzsprühkorrosion, chemische Belastung oder Leistung bei Temperaturwechseln. Für Außen- und Küstenstandorte sind gesonderte Anforderungen oder Prüfnachweise für diese Faktoren zu berücksichtigen. Ein Steckverbinder, der allein hinsichtlich seiner IP-Eigenschaften hervorragend ist, kann ohne die richtigen Materialien und Oberflächen schnell altern, wenn er harten Stößen, starker Sonneneinstrahlung oder Salz ausgesetzt ist.

Kurzübersicht: Wasserschutzstufen

Wasserstand | Typische Idee hinter dem Test | Feldübersetzung |

IPX5 | Standard-Strahlstrahl mit definierter Entfernung und Durchflussmenge | Regen und Abspritzen aus der Ferne |

IPX6 | Stärkerer Strahl | Stärkerer Schlauch- und Schlagregen |

IPX7 | Eintauchen bis zu einer definierten Tiefe und Dauer | Vorübergehendes Untertauchen oder Wasseransammlungen |

IPX9 / 9K | Hochtemperatur- und Hochdruckstrahlen aus verschiedenen Richtungen | geeignet für geregelte Waschvorgänge mit fester Geometrie. |

Die IP-Schutzart eines EV-Steckers ist weit mehr als eine technische Spezifikation – sie ist ein direkter und zuverlässiger Indikator für dessen Qualität, Sicherheit und Haltbarkeit. Eine höhere Schutzart, wie der von Workersbee anerkannte IP67-Standard, weist auf ein Produkt hin, das den Elementen standhält, gefährliche Stromausfälle verhindert und über Jahre hinweg zuverlässig funktioniert.

Achten Sie bei der Auswahl Ihres nächsten Ladekabels oder Ihrer Ladestation nicht nur auf Preis und Ladegeschwindigkeit. Achten Sie auf eine hohe IP-Schutzart. Sie ist die beste Garantie dafür, dass das Produkt nicht nur für ideale Bedingungen, sondern auch für die reale Welt mit all ihren chaotischen, unvorhersehbaren Herausforderungen entwickelt wurde. Die Investition in einen Stecker mit hoher IP-Schutzart bedeutet Sicherheit, Zuverlässigkeit und vor allem Vertrauen.